Demolition projects require powerful and efficient equipment to break down structures quickly and safely. One of the most essential tools in demolition is the hydraulic breaker machine. Used extensively in construction, mining, and excavation, hydraulic breakers help contractors complete projects efficiently by breaking through tough materials such as concrete, rocks, and asphalt. This article explores the role of hydraulic breakers for excavators in demolition projects and why they are a must-have for any heavy-duty task.

What Are Hydraulic Breakers?

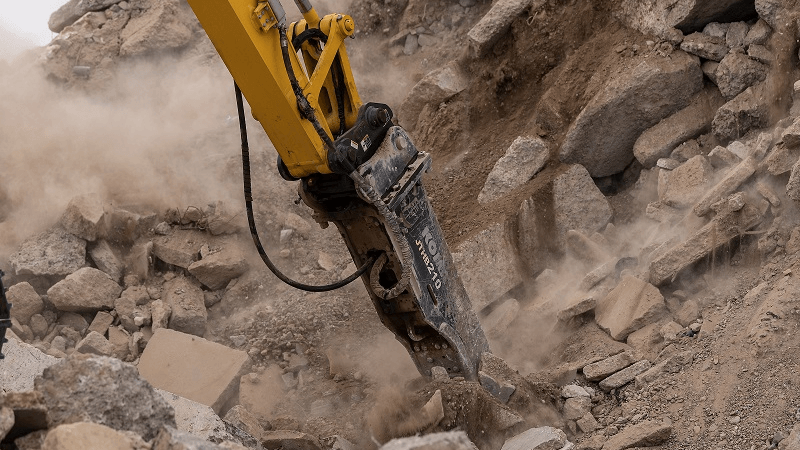

A hydraulic rock breaker is a powerful attachment used with excavators, skid steers, and backhoes to demolish solid materials. It operates using hydraulic power to generate high-impact energy, effectively breaking through concrete, rock, and reinforced structures. The machine consists of a hammer and chisel, which exert forceful blows on the surface, making demolition easier and faster.

The Importance of Hydraulic Breakers in Demolition Projects

1. Efficient Material Breakdown

Demolition involves tearing down buildings, bridges, roads, and other structures made of tough materials like concrete and stone. Hydraulic breakers for excavators efficiently break down these materials into smaller, manageable pieces, making it easier for workers to clear the site.

2. Versatility in Applications

Hydraulic breakers are not limited to a single type of demolition. They can be used in various applications, including:

- Concrete breaking: Removing old foundations, pavements, and slabs.

- Rock excavation: Breaking through hard rock formations in construction sites.

- Bridge demolition: Tearing down reinforced concrete bridges.

- Roadworks: Removing asphalt and concrete roads efficiently.

3. Time and Cost Efficiency

Using a hydraulic breaker machine significantly reduces demolition time compared to manual or traditional methods. The powerful impact force of the breaker speeds up the process, leading to faster project completion and lower labor costs. This efficiency helps contractors save both time and money.

4. Safety and Precision

Demolition is a high-risk job, but using hydraulic breakers for excavators enhances safety. Operators can control the breaker from inside the excavator, reducing direct exposure to falling debris and hazardous conditions. Additionally, hydraulic breakers offer precision in breaking, minimizing unnecessary damage to surrounding structures.

Key Features of Hydraulic Breakers

Key Features of Hydraulic Breakers

Modern hydraulic breaker machines come with advanced features that enhance performance and durability. Some key features include:

- Auto Lubrication System: Reduces wear and tear by ensuring proper lubrication.

- Energy Recovery System: Increases efficiency by reusing rebound energy.

- Soundproofing Technology: Lowers noise levels, making them suitable for urban demolition projects.

- Adjustable Impact Power: Allows operators to modify power settings based on material hardness.

How to Choose the Right Hydraulic Breaker for Your Demolition Project

Selecting the right hydraulic rock breaker depends on several factors, including:

1. Excavator Compatibility

Ensure the breaker is compatible with your excavator’s hydraulic system. Different excavators require specific breaker sizes and hydraulic flow rates.

2. Impact Energy and Frequency

Choose a breaker with sufficient impact energy and frequency based on the material you are demolishing. Heavy-duty projects require high-impact force.

3. Durability and Maintenance

Opt for a hydraulic breaker machine that is durable and easy to maintain. Features like auto-lubrication and wear-resistant components enhance longevity.

4. Noise and Vibration Levels

For urban projects, select a breaker with noise and vibration reduction features to comply with environmental regulations and minimize disturbances.

Maintenance Tips for Hydraulic Breakers

Proper maintenance ensures the longevity and efficiency of hydraulic breakers for excavators. Here are some essential maintenance tips:

- Regular Inspections: Check for leaks, worn-out parts, and cracks before and after use.

- Lubrication: Use the right grease to prevent overheating and reduce wear.

- Proper Storage: Store in a dry place to prevent rust and corrosion.

- Check Hydraulic Pressure: Ensure the excavator’s hydraulic system is operating at the recommended pressure levels.

Conclusion

Hydraulic breakers play a crucial role in demolition projects by providing efficient, safe, and precise material breakdown. Whether demolishing concrete structures, breaking rocks, or removing roadways, hydraulic breakers for excavators offer unmatched power and versatility. Investing in the right hydraulic breaker machine ensures faster project completion, cost savings, and enhanced safety for demolition workers. If you are involved in demolition or excavation work, using a hydraulic rock breaker is the key to achieving outstanding results.