Introduction

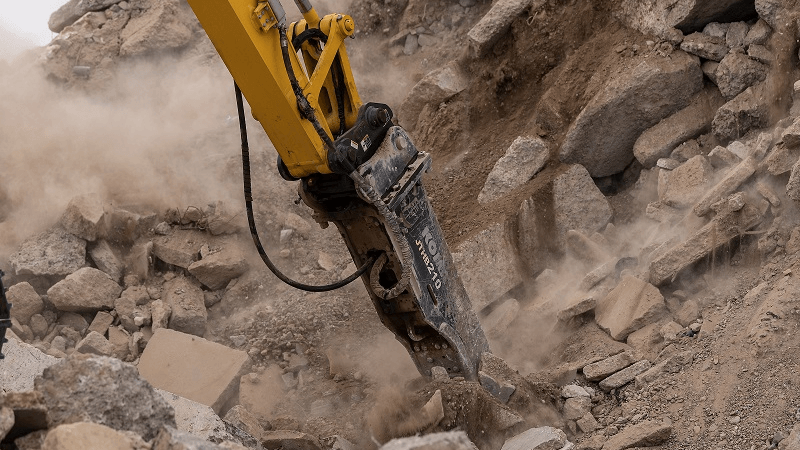

In the ever-evolving world of construction and mining, efficiency, safety, and productivity are key factors determining success. One revolutionary piece of equipment that has transformed these industries is the Hydraulic Rock Breaker. This powerful attachment is designed to break through hard surfaces like rocks, concrete, and asphalt with precision, making it an essential tool for excavation, demolition, and quarrying operations.

This blog will explore how Hydraulic Breaker Machines have revolutionized construction and mining, improving productivity, reducing costs, and enhancing safety.

The Role of Hydraulic Rock Breakers in Construction

Construction projects, whether large-scale infrastructure development or small residential projects, often involve breaking through tough surfaces. Hydraulic Rock Breakers have changed the way construction professionals handle these challenges by offering a more efficient and cost-effective solution compared to traditional methods such as blasting or manual chiseling.

1. Increased Efficiency and Speed

One of the major benefits of using a Hydraulic Breaker Machine in construction is the significant boost in efficiency. Unlike manual labor or mechanical drills, these machines deliver high-impact energy, quickly breaking down hard materials and reducing the time needed for excavation or demolition tasks.

2. Versatility in Applications

Hydraulic Rock Breakers can be attached to various types of equipment, including excavators, backhoes, and skid steers, making them a versatile solution for different construction projects. They are used for:

- Demolishing old buildings and concrete structures

- Road construction and repair

- Trenching and foundation excavation

- Landscaping and rock removal

3. Cost Reduction and Labor Efficiency

By eliminating the need for extensive manual labor and expensive explosives, Hydraulic Breaker Machines help construction companies reduce operational costs. They require minimal manpower to operate, allowing companies to allocate resources more effectively and increase overall project profitability.

4. Enhanced Safety

Traditional demolition methods, such as blasting, pose significant safety risks. Hydraulic Rock Breakers provide a safer alternative by enabling precise material removal without the dangers associated with explosions, dust clouds, or flying debris. Additionally, operators can control these machines remotely, further reducing the risk of workplace injuries.

The Impact of Hydraulic Rock Breaker in Mining

The mining industry relies on powerful equipment to extract minerals and ores from the earth efficiently. Hydraulic Breaker Machines have become indispensable in mining operations due to their ability to break through hard rock formations with minimal effort and maximum efficiency.

1. Efficient Ore Extraction

Mining operations require the breaking of large boulders and solid rock formations to access valuable minerals. Hydraulic Rock Breakers make this process more efficient by delivering powerful, controlled impacts that break rocks into manageable sizes, reducing the need for secondary crushing and speeding up the extraction process.

2. Reduced Environmental Impact

Traditional blasting techniques create dust pollution, vibration, and noise, which can harm the environment and nearby communities. Hydraulic Breaker Machines offer a more eco-friendly alternative by minimizing vibrations and reducing the need for explosives, thus decreasing the environmental footprint of mining operations.

3. Operational Cost Savings

Using Hydraulic Rock Breakers instead of explosives or heavy drilling equipment reduces fuel consumption and maintenance costs. Additionally, the precision of these machines helps reduce material wastage, making mining operations more cost-effective.

4. Improved Worker Safety

Mining environments are often hazardous due to unstable rock formations and deep excavation sites. Hydraulic Breaker Machines allow operators to break rocks from a safe distance, reducing the risk of cave-ins, falling debris, and worker injuries.

Choosing the Right Hydraulic Rock Breaker

Selecting the right Hydraulic Breaker Rock Machine for construction or mining depends on several factors, including:

- Size and Power: The machine should match the size and type of material to be broken.

- Compatibility: It should be compatible with the existing excavators or loaders.

- Durability: Heavy-duty materials and advanced engineering ensure long-lasting performance.

- Maintenance Requirements: Low-maintenance models help reduce downtime and operating costs.

Conclusion

The Hydraulic Rock Breaker has revolutionized the construction and mining industries by offering a more efficient, cost-effective, and safer alternative to traditional rock-breaking methods. Its versatility, power, and precision make it an essential tool for modern infrastructure development and mineral extraction.

As technology advances, Hydraulic Rock Braker machines continue to evolve, becoming more efficient and environmentally friendly. For construction companies and mining operators looking to enhance productivity and safety, investing in high-quality Hydraulic Rock Breakers is a game-changer.